Thermographic Inspections Chicago, IL

Level II Certified

Fully Insured

Service Nationwide

Our Infrared Services

Detecting Temperatures

Detecting temperature differences with infrared thermography allows us to provide a broad spectrum of services, limited only by one's imagination. Our focus is on three types of services: Electrical / Mechanical, Roof Moisture and Building Envelope Energy Loss.

Report

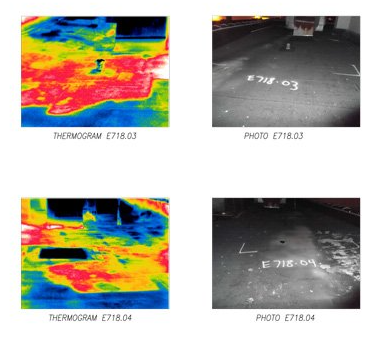

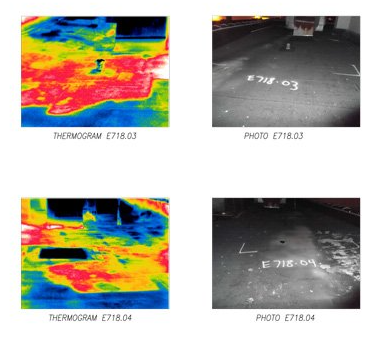

Our thermographic roof scans identify wet insulation inside the roof system and invisible to the naked eye. Often the source of damaging leaks, it is also crucial to remove these wet areas before reroofing.

Our roof scans on low sloped roofs identifies moisture trapped in the insulation and below the surface membrane. During the day, the sun heats the entire roof system and when the sun goes down, the roof cools down - except where there is moisture laden insulation. These areas remain warmer well into the night. Using our thermal camera we identify wet areas and mark them directly on roof surface and document on a scaled roof drawing. Our clients then have the information they need to order the necessary repairs and not trap damaging moisture in the roof system.

IR Inspections

The benefits of infrared electrical and mechanical scanning are well known: Identifying problems in these systems will prevent unscheduled downtime and costly repairs.

IR Heat Loss Inspections

Our thermographic roof scans identify wet insulation inside the roof system and invisible to the naked eye. Often the source of damaging leaks, it is also crucial to remove these wet areas before reroofing.

Building Envelope Energy Loss Surveys

Energy loss in the building envelope can be easily identified using our thermal cameras. Missing insulation in attics and sidewalls allows heat to escape the building wasting energy - and money. This is also true of leaky windows and doors. The correction of these issues is often extremely cost-effective because of the relatively low cost of caulk and insulation.

Top Quality Reports

Whether for roof, electrical or heat loss inspections, our reports give you the information you need to make the correct decisions regarding your facility. We pinpoint the problem areas in our electronic reports which are delivered within one week of survey completion.

FAQs

-

What is Thermography?

Thermography is the workmanship and study of utilizing infrared to notice and quantify the temperature of an item's surface. Infrared is certifiably not an "X-Ray" innovation; it can't "see" through objects. Just warmth, transmitting from the outside of an item, is noticeable to the infrared imager.

Infrared radiation involves a little segment of the absolute electromagnetic range. It is situated at frequencies just beneath the most reduced frequencies of the apparent light segment of the range, which is red, subsequently the name infrared or underneath the red. Infrared frequencies range from is .1um to 1000um.

Each actual item is comprised of particles and electrons which vibrate; the temperature of an article relies upon how quickly its electrons are vibrating. The quicker they vibrate, the higher the energy levels and the hotter the article gets. As temperature builds, the frequency diminishes

-

Why infrared?

Infrared thermography for building science applications is the most progressive non-damaging testing/assessment application for building investigation administrations. It can distinguish building deserts past the noticeable investigation recognizing potential issues that can cost a lot more money to fix down the road.

-

Can the inspection be performed without any service interruptions?

Almost all electrical equipment has a service interlock that allows access for inspection without shutting off the power.

-

Can the inspection be performed without any service interruptions?

Almost all electrical equipment has a service interlock that allows access for inspection without shutting off the power.

-

How long will the inspection take?

The limiting factor is usually how fast the covers can be removed/replaced.

-

What kind of report can I expect at the end of the inspection?

A full composed report itemizing every one of the warm inconsistencies distinguished with a warm and full-shading picture for every issue. Affirmed Infrared will likewise suggest fix methods dependent on the seriousness of the issue and the criticality of the piece of hardware. You will likewise get a full rundown of all the hardware that was assessed.

Why Infrared Inspections, Inc. is so popular?

Infrared Inspections Inc. has gained immense popularity for its exceptional thermographic inspection services in Chicago, IL. Their skilled technicians utilize cutting-edge infrared technology to conduct thorough and accurate thermographic inspection s of various systems and components. What sets Infrared Inspections Inc. apart is their meticulous attention to detail during thermographic inspections , ensuring that every potential issue is identified and addressed promptly. Clients in Chicago, IL, trust Infrared Inspections Inc. for their reliable and insightful thermographic inspections , which provide valuable data for maintenance and troubleshooting purposes. With a track record of excellence, Infrared Inspections Inc. continues to be a preferred choice for businesses seeking top-notch thermographic inspection services.

All Rights Reserved | Infrared Heat Scans