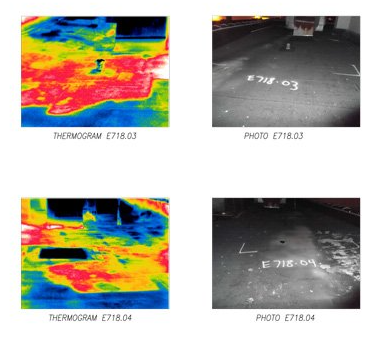

Thermography Inspections

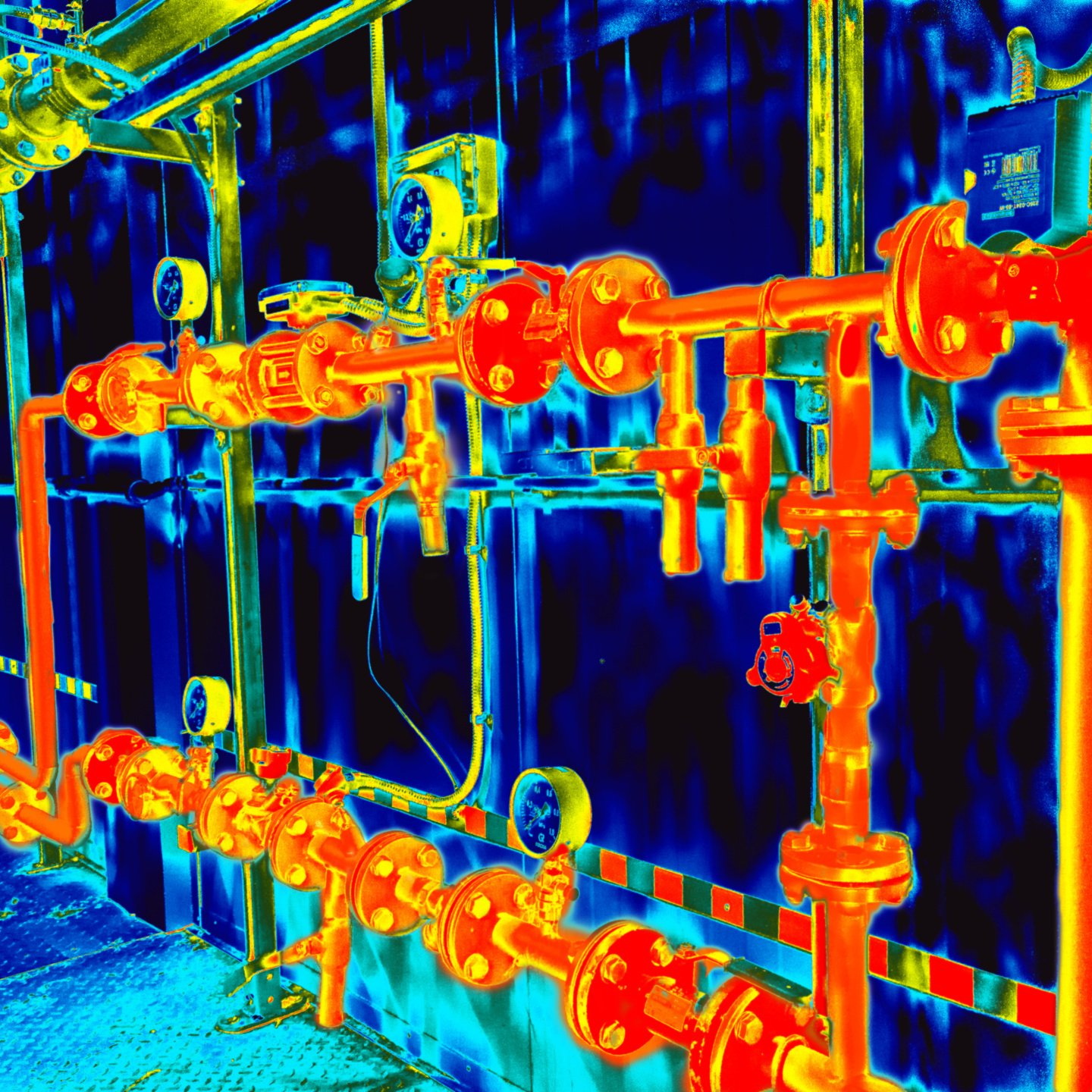

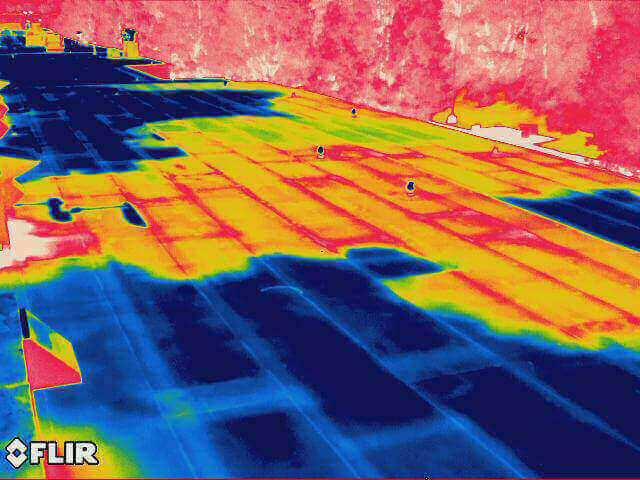

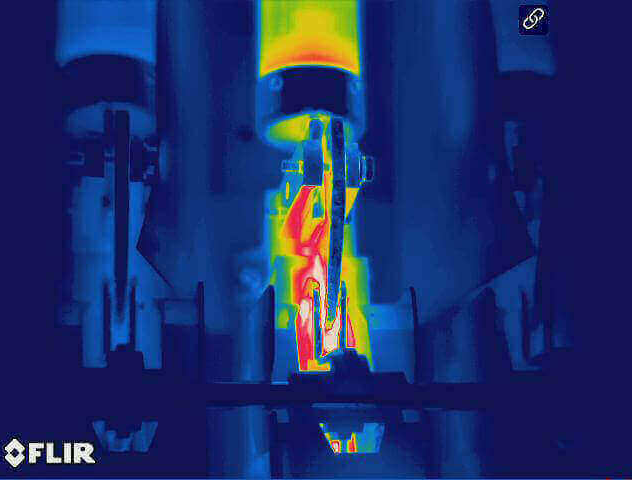

Thermography allows for us to see the temperature of a building. Our main services are detecting roof moisture, heat loss, and inspecting electrical and mechanical fixtures.

Level II Certified

Fully Insured

Service Nationwide

About Us

Infrared Inspections, Inc. was established in 1985, the early days when thermography was beginning to be used as a predictive tool for roof moisture, electrical and heat loss inspections. We are very experienced in what we do, and take thermography inspection to the next level. We use our better judgment, research and skills to give you the most accurate inspection results. Since 1985, technology has drastically improved and the benefits of of these inspections has increased greatly. Tested and trusted. Qualified and bona fide. For an experienced expert, you can consider us the go-to choice. Don't wait if you have any infrared inspection needs, call us for any questions today!

Our

Infrared Services

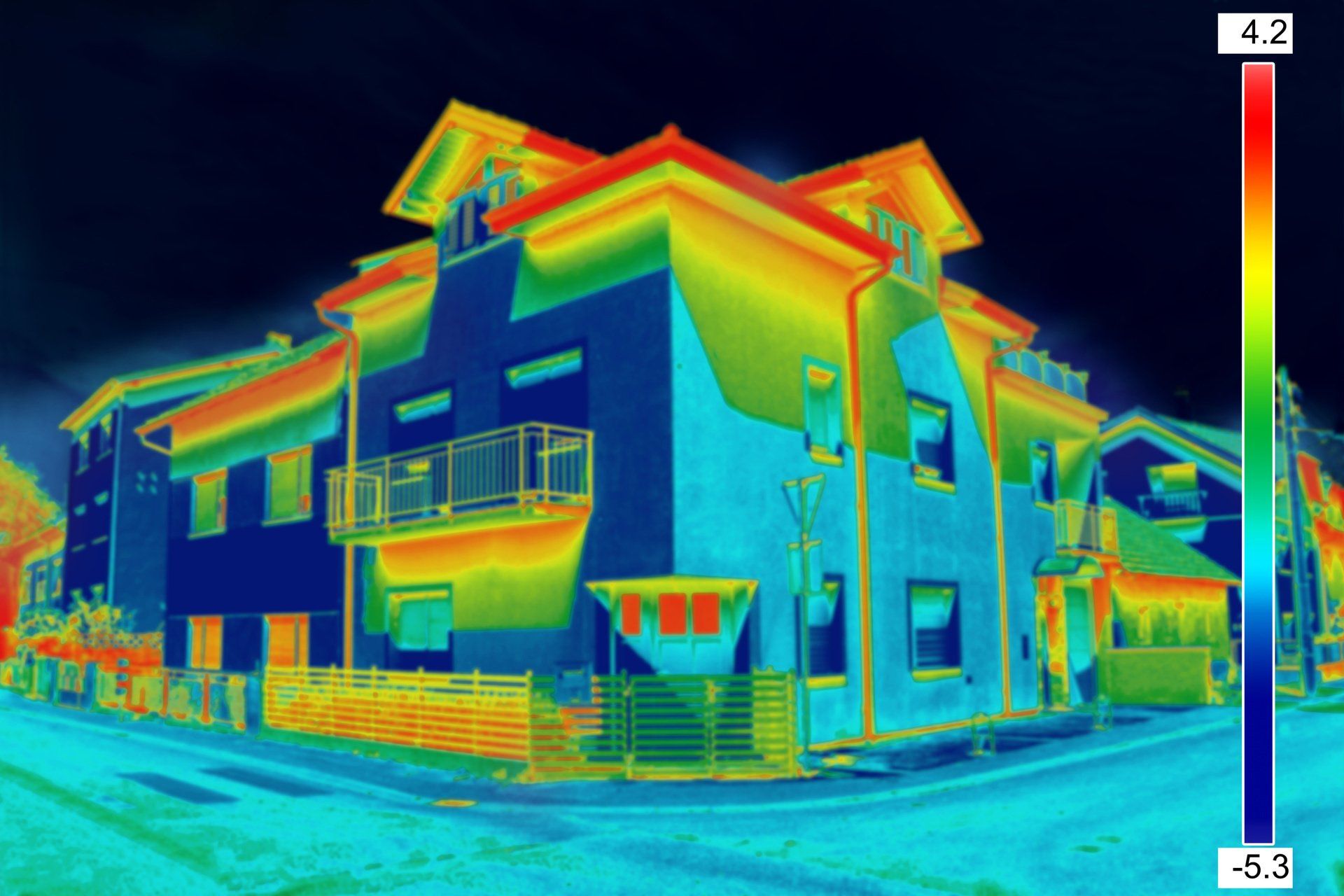

Building Envelope Energy Loss Surveys

Energy loss in the building envelope can be easily identified using our thermal cameras. Missing insulation in attics and sidewalls allows heat to escape the building wasting energy - and money. This is also true of leaky windows and doors. The correction of these issues is often extremely cost-effective because of the relatively low cost of caulk and insulation.

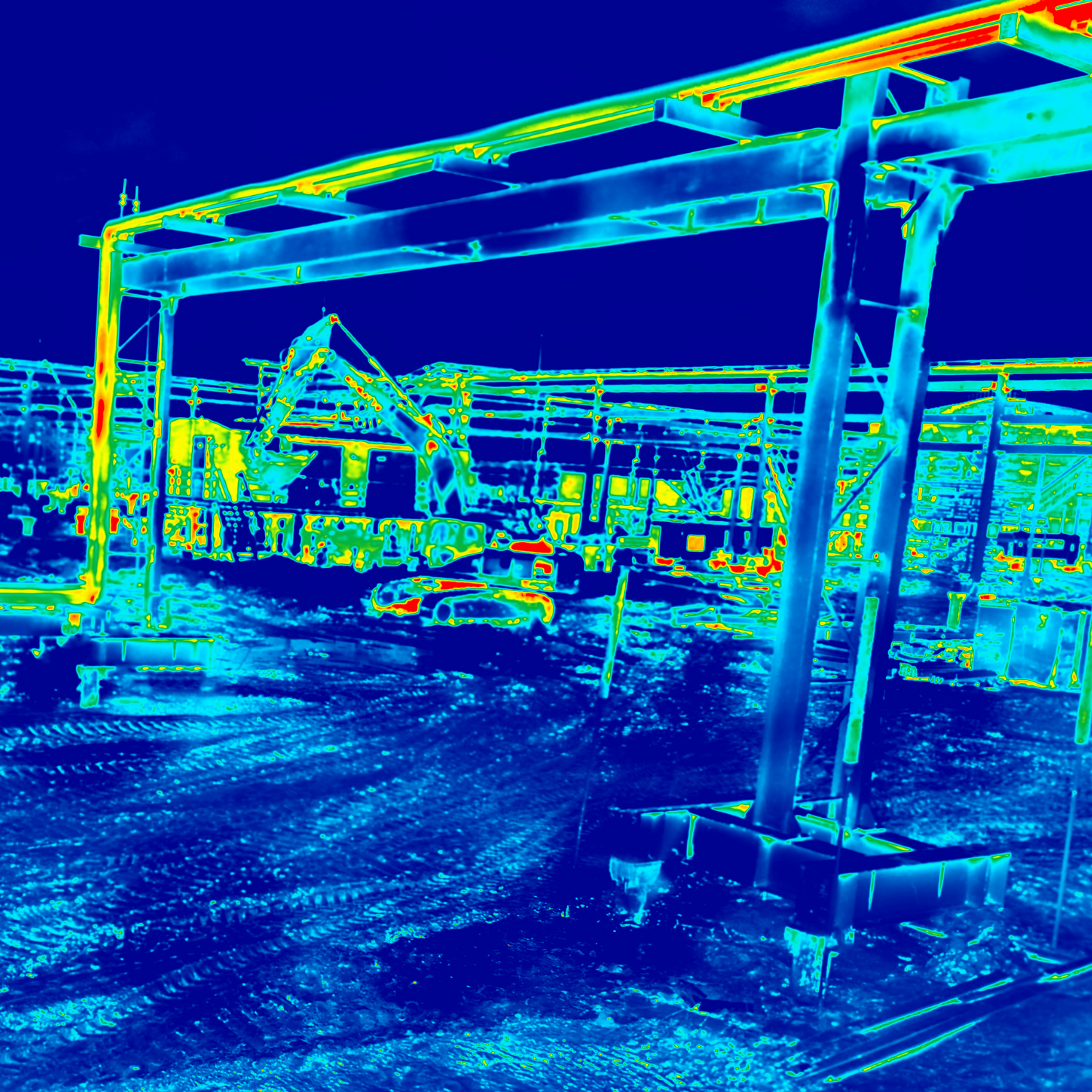

Top Quality Reports

Whether for roof, electrical or heat loss inspections, our reports give you the information you need to make the correct decisions regarding your facility. We pinpoint the problem areas in our electronic reports which are delivered within one week of survey completion.